Consolis' international commitment and undertakings ensure that our environmental efforts will have a real impact and lead us in the right direction:🌎 By 2030, we will have launched climate-neutral concrete, and our long-term vision is for all concrete to be climate-neutral. Consolis has already launched the Consolis Green Spine Line® - our certified prefab solutions with CO2 emissions at least 15% lower than the local industry standard.

🌎 At Consolis, we have decided to take a leading role in making our industry sustainable, with the aim of achieving climate neutrality by 2050.

🌎 At Consolis, we are committed to increasing the circular economy. By recycling and reusing concrete, we can reduce the use of raw materials and thus further reduce our impact on the environment.

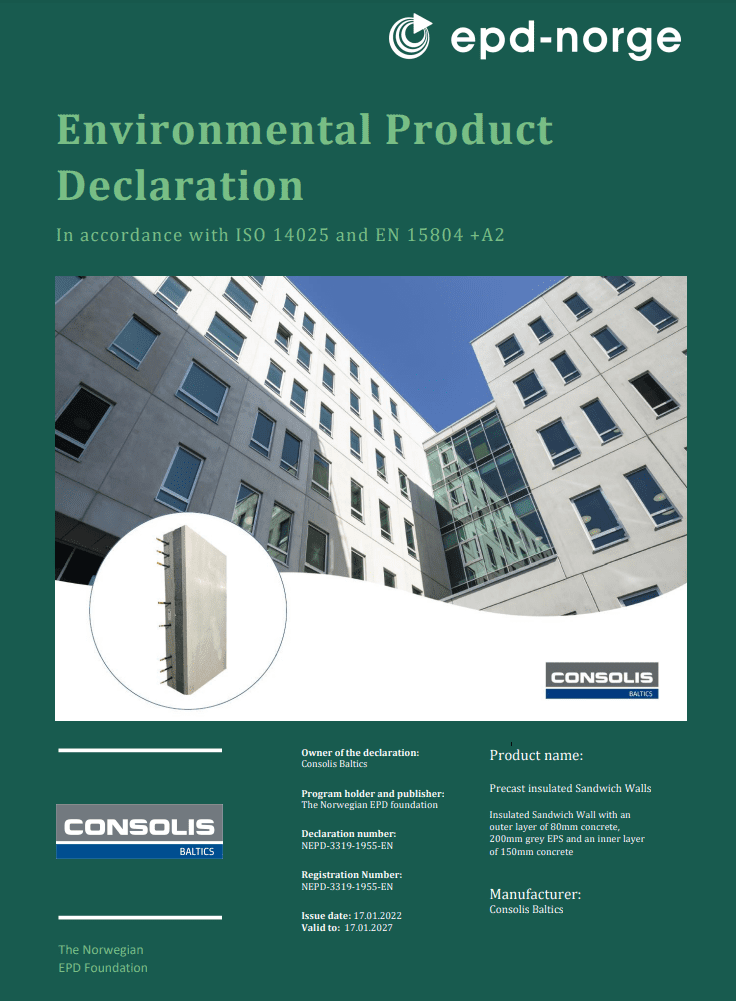

🌎 We promote the progress of ourselves and our industry by measuring our environmental efforts, and for this we use environmental product declarations (EPDs).

🌎 87 percent of Consolis' finished products are manufactured in 36 factories that apply a certified environmental management system

ISO 14001.🌎 We use the CODE's environmental standard - in most of our factories, Consolis' own LEAN-based concept is used which ensures compliance with Consolis' high standards throughout the entire production process.

🌎 The well-being of our employees, partners, customers and guests is our priority and we strive for an accident-free work culture.

🌎 Our goal is to be an attractive employer - ensuring safe and collaborative workplaces and an environment where people and teams achieve great results.

Read more here:

Consolis Sustainability