BIM (Building Information Modeling) is a building information modeling, organizing and managing platform that involves all building project partners. The BIM includes the model of the building (with all its properties) and enables the use of this model for all partners.

BIM`s main advantages:

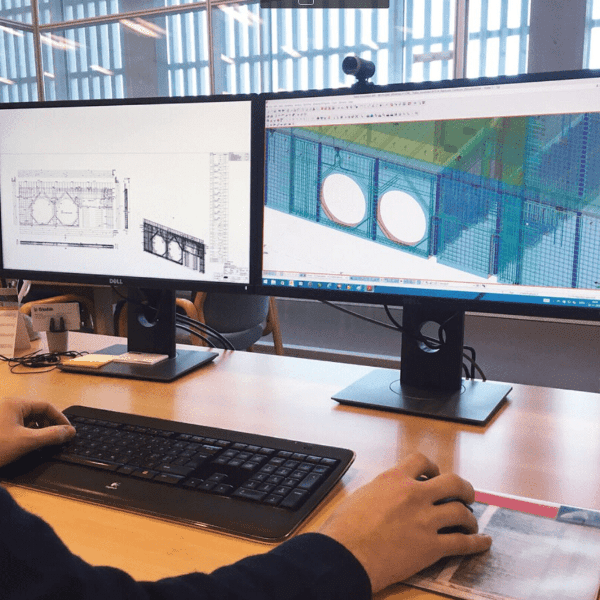

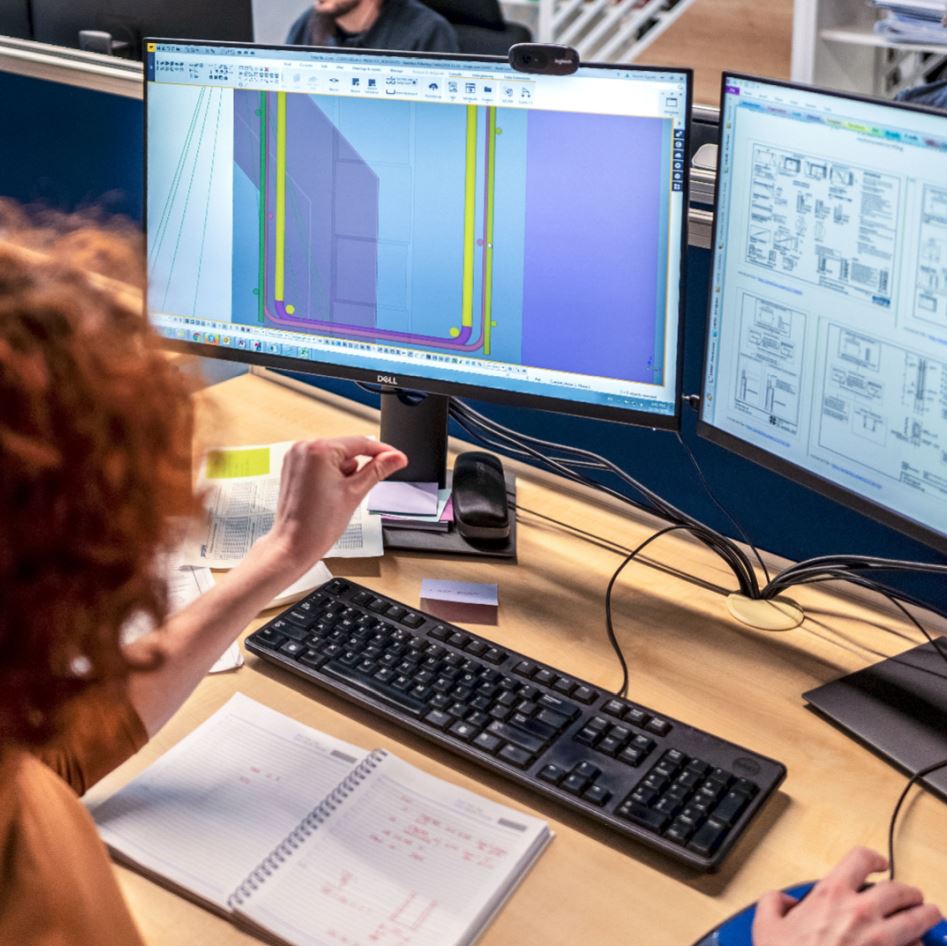

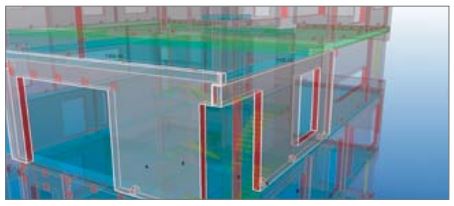

Projekteerimises kasutame Tekla BIM tarkvara. Juba pakkumise staadiumis loome kavandatavast hoonest 3D mudeli. See mudel jääb kogu edasise töö aluseks, mida vastavalt projekti staadiumitele järjest täiendame ja täpsustame.

The construction of the bidding project is based on the architect's architectural project in ifc format (see detail in the lower part of the text) or as AutoCAD dwg file.

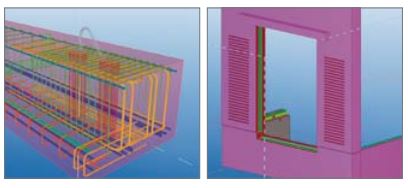

On the contrary, it is possible to act as the basis for the work to give the created constructive model to the architect. It is also possible to use a constructive model to provide designers with special components to which they can add ventilation, piping, cabling, etc. - information, which in turn serves as the starting point for our design.

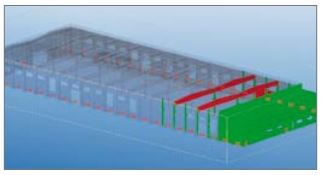

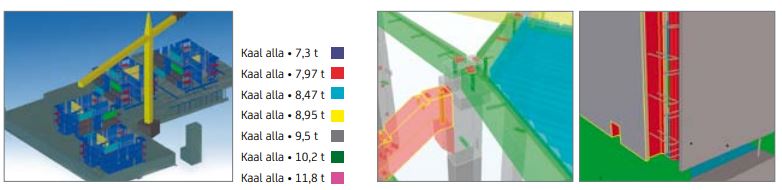

The bid model shows the structure and elemental division of the building (panels and shapes of panels). You can make a summary of the volumes and the weight of the item.

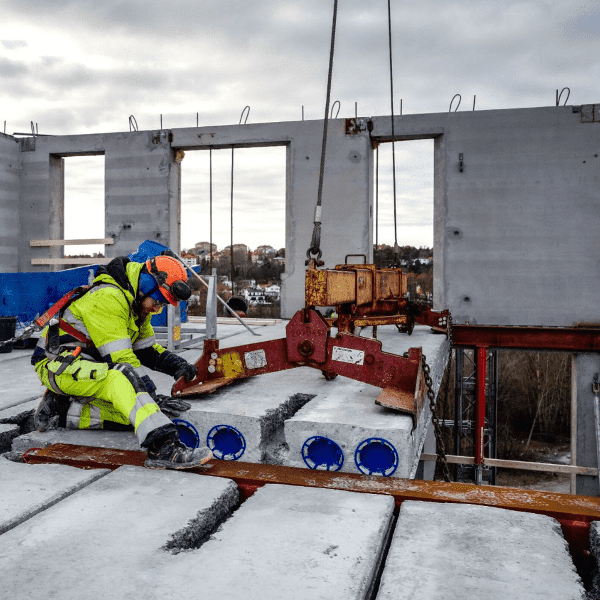

The model will be supplemented when drafting the work. Elements are added environmental classes, layers of protection, tolerances, finishes, fire resistance, thermal conductivity and other characteristic information. The armature and formwork, ventilation openings, electric sinks, and the like are applied to the model. The information entered is digitized in our production planning software. The model also generates product lines for the elements.

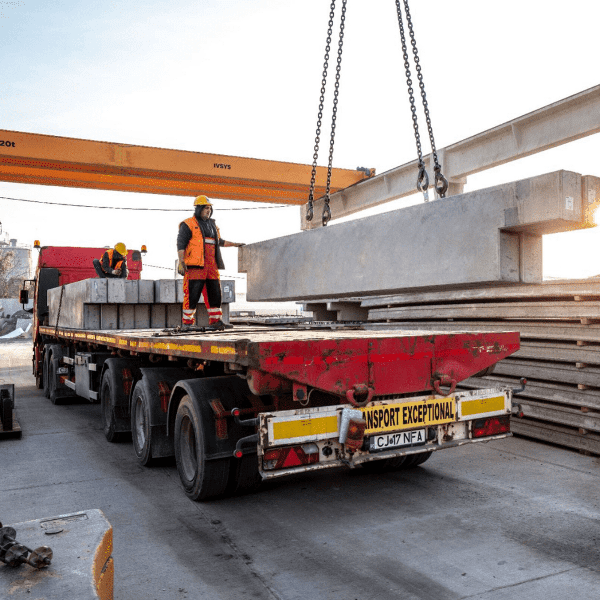

On the basis of the installation steps and planned delivery dates introduced into the model, all parties to the project will see the dates of casting, delivery and installation, and items delivered and installed. Production can look at the design stage of the elements. It is possible to monitor the progress of the project in real time.

The use of the model from the bidding phase will greatly save time and avoid errors.

Download: BROCHURE.

BENEFITS of the element industry

IFC - In order for BIM ideology to work, it is necessary to follow strict, uniform standards. Data is saved in the ifc file format. IFC (International Foundation Classes) is a data model developed by the international organization buildingSMART to enable digital information exchange (synchronization) between different parties in the field of construction (architecture, constructive part, ventilation, heating, electricity, etc.). IFC is registered as ISO 16739: 2013.