The use of reinforced concrete elements in infrastructure facilities offers several advantages:

- precision and quality of factory work;

- the quality of the factory-made concrete surface;

- several different finishing options;

- elements can be provided inclination with casting;

- elements can be casting communication utilities at the factory;

- the dependence of the work on the weather conditions has been minimized;

- the speed of work on the site;

- minimum requirement for formwork on the site;

- in parallel with the installation, the possibility of passing traffic is maintained.

We offer:

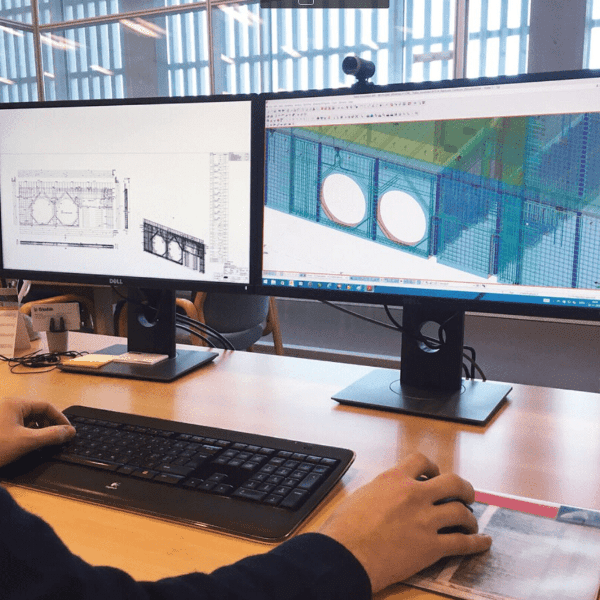

- constructive design of structures;

- production of precast elements

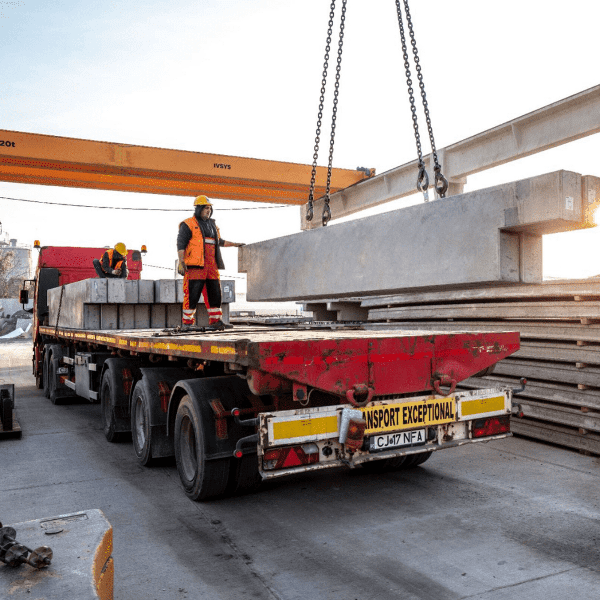

- delivery of precast elements

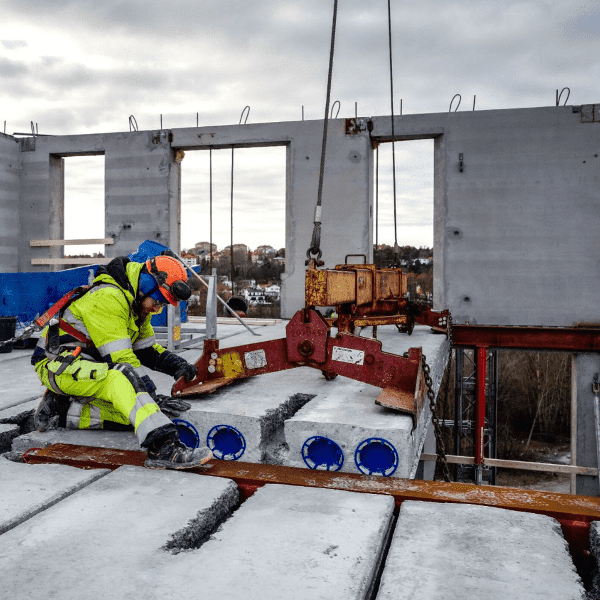

- assembly of elements and cast-in-situ works necessary for the integrity of the structure

ZIP beam bridges

E-Betoonelement has been offering and producing solutions for precast concrete bridges since 2000. The first bridge based on ZIP beams, the 33m long Kärkna Bridge, was built in the same year on the Tartu-Jägeva highway 6,6 km over River Amme. It was followed by the bridges of the Estonian Power Plant, Sirgala, Korbatu and Puurmani. In 2008, the 160 m Vaida viaduct and the 90 m Aruvalla viaduct were built.

The ZIP beam superstructure consists of prestressed ZIP beams which have an inverted T-shape cross-section and are assembled side by side. Beams are connected by a cast-in-situ deck slab and reinforced concrete cross-girders at supports.

ZIP-beams can also be placed at a longer centre-to-centre distance when there is no need to consider the impact load from below (for example when the clearance exceeds the minimum permitted height or when the bridge crosses a non-navigable river). In this case the deck is created as a composite structure using approximately 70-80 mm thick precast concrete slabs as formwork. These precast deck slabs are used to cover the gaps between beams, creating a formwork which supports the load of the cast-in-situ topping and after the monolithic part has hardened they act together carrying traffic loads.

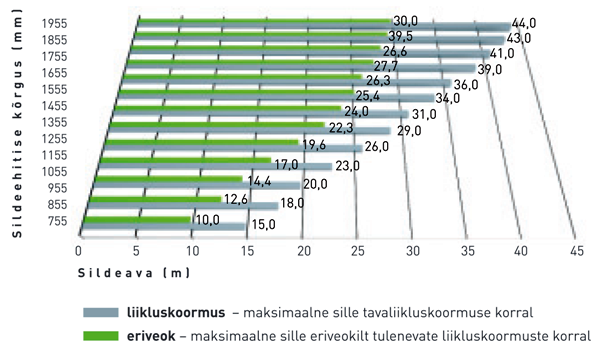

Maximum bridge plates for bridges and viaducts resolved by ZIP beams.

- this graph can be used only for the initial determination of the height of the bridge structure cross section.

- the load models used comply with the Estonian design rules EPN-ENV 1.3.

- The height of the bridge building includes a bridge and a monolithic concrete slab.

Segment-tunnel

The tunnel cross-sectional elements or segments form the supporting structure of a segment tunnel. On the site, the segments are assembled one after the other and, if necessary, the tunnel body is longitudinally tensioned. On the outside of the segments, there are concrete brackets to support the access panels, and it is possible to cast cable ducts and similar accessories into the element at the factory. The inner surfaces of the tunnel are cast against the mould and this allows the use of different surface finishing techniques.

Places of use:

– pedestrian and cyclist tunnels;

– cattle and wildlife tunnels;

– culverts.

Segments dimensions

Possible typical internal dimensions are (height x width)

2,50×3,50 m

Typical length of a single segment is 950 mm.

The mass of a segment with maximum internal dimensions of 2.5×3.5 m is 10.5 t.

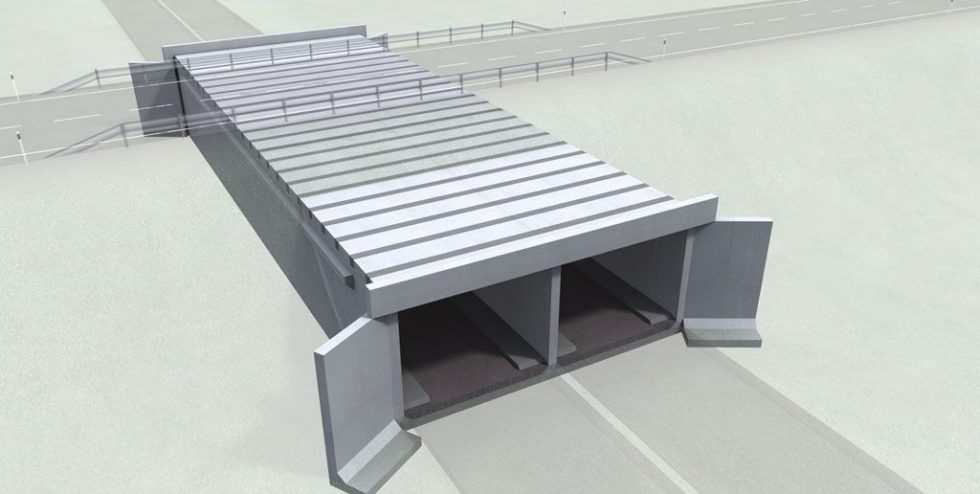

Slab tunnel

Slab tunnel solution consists of L-shaped supporting walls, cast-in-situ floor and prestressed ceiling slabs. Prestressed slabs with a rectangular cross-section and smooth surface can span up to 10 m. This solution is also suited for constructing multi-span structures.

Beam tunnel

The idea of a beam tunnel is similar to that of a slab tunnel only the load-bearing ceiling elements are in this case prestressed beams (see ZIP beams) which are assembled side by side. There are openings in the beam webs for installing transverse reinforcement. The space between beams is reinforced and filled with concrete. This makes it a full cross-sectional deck structure. This solution is suitable for spans of 10-16 m. Walls can be either L-shaped supporting wall elements or straight wall panels combined with an in-situ floor.

We manufacture noise-barrier wall elements and complete solutions. Please contact our salesengineer.

The ViaPlus box beam is a closed cross-sectional bridge beam, which is cast in the factory either in one or two stages depending on the geometry of the beam. We use this type of beam as an edge beam (trapezoidal section) to give a more smooth-shaped deck edge to the bridge to be assembled. The first object for which we manufactured such beams were viaducts No. 1 and 2 of the Kroodi multi-level intersection in Maardu. The ends of the beam are in full cross-section in the zone close to the support, but for the rest of the length there is a gap in the middle of the body, which is separated by stiffness ribs in ~ 5m steps.

Possible dimensions of the E-Betoonelement box beams:

– width 950mm

– height 1000mm

- lenght up to 27m

- weight up to 42t

In the Netherlands, the country of origin of a box beam, this solution is widespread, offering a number of options for the construction of a bridge deck.

– The deck constructed with the beams can be further prestressed in the longitudinal and transverse directions

– Continuous bridges can be built

– Greater torsional rigidity

- No need for monolithic casting

- The duration of deck construction brought to minimum

Precast deck plates together with cast-in-situ topping create a composite structure. There are two types of plates depending on whether they are used for constructing a new superstructure or for reconstructing an existing one.

About the solution

When building a new bridge deck, plates are assembled directly on concrete or steel beams. Openings are left in the precast plates for the shear dowels in the beams. Dowel joints and connections between plates are cast together after the assembly of plates. Plates are further joined together by cast-in-situ topping which is approximately 100 mm thick. The lower surface of the precast deck plates is a smooth formwork finishing. The top surface of the element can be cast with initial double-sided transverse slope. When an existing bridge is being reconstructed and the old and usable concrete deck is partially preserved, it is possible to use precast deck plates which are installed on the existing parts. In this case the plates are thinner and lighter. The top side of the plate can then be cast as a mould surface and the lower surface remains a steel floated one.

Advantages

- Enables to cast the bridge deck in factory conditions

- During the casting of bridge deck and the initial hardening period of concrete there are no fluctuations of the outdoor environment (heat, extreme cold, excessive rain or snow)

- During the first week, concrete hardens in stable indoor conditions, thereby reducing the risk of cracks

- There is no need to use formwork on site and it is significantly easier to build a bridge over a water body that has a changing water level or a river-bed with poor load-bearing capacity

- Safety at construction site improves since the element after assembly becomes immediately a platform for carrying out subsequent works

- Saves construction time since elements can be cast at the factory while preparations are made at the construction site

- Concrete surfaces are of high quality and the dimensions of elements are checked and double-checked before they are delivered to the construction site

Slab parameters

The recommended dimensions of precast slab elements should not exceed 10.0x2.4 m. These dimensions are in the range that allow regular transport and no special permits are needed for carriage.

The maximum mass of one slab is up to 12.5 tons and slabs are carried in pairs.

The time required for assembling one slab is less than 30 minutes.

Assembly

- Bridge deck plates are assembled

- There is a groove in the side edges of deck plates which are equipped with sealings at the factory in order to prevent cement paste from seeping through between elements while joints are being cast

- Horizontal reinforcement is installed in the connections between the slabs

– Dowel joints and connections between the slabs are cast together

- Border elements are assembled

- Reinforcement of the in-situ topping is placed and the topping is then cast

– Joints between border elements are finished with elastic mastics

Scope of works

We offer:

- technical design of the superstructure (precast concrete beams, deck plates and in-situ topping)

- preparing shop-drawings of precast elements;

- preparing shop-drawings of precast elements

- production of precast elements

- delivery of precast elements

- assembly of elements and cast-in-situ works necessary for the integrity of the structure.

T-beam bridges

We have manufactured T-shaped bridge beams which are mainly used for reconstructing old precast beam bridges.

Border and edge elements for bridges

Precast reinforced concrete border and edge elements can have various cross-sections. The shell elements are usually 3-4 m long but we have also manufactured pieces up to 7.5 m long pieces. These elements can be used for both cast-in-situ and composite decks. Elements are fixed with temporary fastenings during assembly and are later connected to the deck by means of protruding rebars or special steel connections. Joints between elements are finished with elastic mastics. Sleeve anchors with internal threads can be cast in the elements for fastening safety barriers. The top and outer surface of elements can be treated with a suitable impregnating substance. The edge element can have a curved design or various patterns including dummy joints, formliner surface or even graphic concrete.

The use of reinforced concrete elements in infrastructure facilities offers several advantages:

- precision and quality of factory work;

- the quality of the factory-made concrete surface;

- several different finishing options;

- elements can be provided inclination with casting;

- elements can be casting communication utilities at the factory;

- the dependence of the work on the weather conditions has been minimized;

- the speed of work on the site;

- minimum requirement for formwork on the site;

- in parallel with the installation, the possibility of passing traffic is maintained.

We offer:

- constructive design of structures;

- production of precast elements

- delivery of precast elements

- assembly of elements and cast-in-situ works necessary for the integrity of the structure

ZIP beam bridges

E-Betoonelement has been offering and producing solutions for precast concrete bridges since 2000. The first bridge based on ZIP beams, the 33m long Kärkna Bridge, was built in the same year on the Tartu-Jägeva highway 6,6 km over River Amme. It was followed by the bridges of the Estonian Power Plant, Sirgala, Korbatu and Puurmani. In 2008, the 160 m Vaida viaduct and the 90 m Aruvalla viaduct were built.

The ZIP beam superstructure consists of prestressed ZIP beams which have an inverted T-shape cross-section and are assembled side by side. Beams are connected by a cast-in-situ deck slab and reinforced concrete cross-girders at supports.

ZIP-beams can also be placed at a longer centre-to-centre distance when there is no need to consider the impact load from below (for example when the clearance exceeds the minimum permitted height or when the bridge crosses a non-navigable river). In this case the deck is created as a composite structure using approximately 70-80 mm thick precast concrete slabs as formwork. These precast deck slabs are used to cover the gaps between beams, creating a formwork which supports the load of the cast-in-situ topping and after the monolithic part has hardened they act together carrying traffic loads.

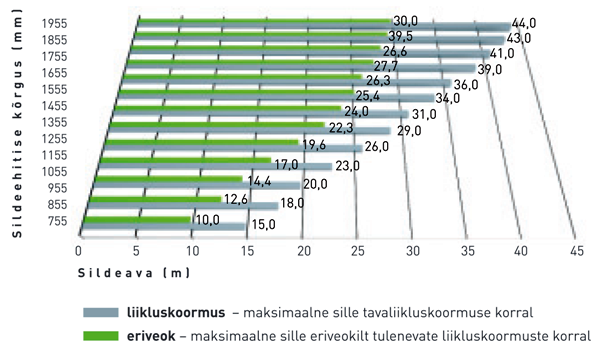

Maximum bridge plates for bridges and viaducts resolved by ZIP beams.

- this graph can be used only for the initial determination of the height of the bridge structure cross section.

- the load models used comply with the Estonian design rules EPN-ENV 1.3.

- The height of the bridge building includes a bridge and a monolithic concrete slab.

Segment-tunnel

The tunnel cross-sectional elements or segments form the supporting structure of a segment tunnel. On the site, the segments are assembled one after the other and, if necessary, the tunnel body is longitudinally tensioned. On the outside of the segments, there are concrete brackets to support the access panels, and it is possible to cast cable ducts and similar accessories into the element at the factory. The inner surfaces of the tunnel are cast against the mould and this allows the use of different surface finishing techniques.

Places of use:

– pedestrian and cyclist tunnels;

– cattle and wildlife tunnels;

– culverts.

Segments dimensions

Possible typical internal dimensions are (height x width)

2,50×3,50 m

Typical length of a single segment is 950 mm.

The mass of a segment with maximum internal dimensions of 2.5×3.5 m is 10.5 t.

Slab tunnel

Slab tunnel solution consists of L-shaped supporting walls, cast-in-situ floor and prestressed ceiling slabs. Prestressed slabs with a rectangular cross-section and smooth surface can span up to 10 m. This solution is also suited for constructing multi-span structures.

Beam tunnel

The idea of a beam tunnel is similar to that of a slab tunnel only the load-bearing ceiling elements are in this case prestressed beams (see ZIP beams) which are assembled side by side. There are openings in the beam webs for installing transverse reinforcement. The space between beams is reinforced and filled with concrete. This makes it a full cross-sectional deck structure. This solution is suitable for spans of 10-16 m. Walls can be either L-shaped supporting wall elements or straight wall panels combined with an in-situ floor.

We manufacture noise-barrier wall elements and complete solutions. Please contact our salesengineer.

The ViaPlus box beam is a closed cross-sectional bridge beam, which is cast in the factory either in one or two stages depending on the geometry of the beam. We use this type of beam as an edge beam (trapezoidal section) to give a more smooth-shaped deck edge to the bridge to be assembled. The first object for which we manufactured such beams were viaducts No. 1 and 2 of the Kroodi multi-level intersection in Maardu. The ends of the beam are in full cross-section in the zone close to the support, but for the rest of the length there is a gap in the middle of the body, which is separated by stiffness ribs in ~ 5m steps.

Possible dimensions of the E-Betoonelement box beams:

– width 950mm

– height 1000mm

- lenght up to 27m

- weight up to 42t

In the Netherlands, the country of origin of a box beam, this solution is widespread, offering a number of options for the construction of a bridge deck.

– The deck constructed with the beams can be further prestressed in the longitudinal and transverse directions

– Continuous bridges can be built

– Greater torsional rigidity

- No need for monolithic casting

- The duration of deck construction brought to minimum

Precast deck plates together with cast-in-situ topping create a composite structure. There are two types of plates depending on whether they are used for constructing a new superstructure or for reconstructing an existing one.

About the solution

When building a new bridge deck, plates are assembled directly on concrete or steel beams. Openings are left in the precast plates for the shear dowels in the beams. Dowel joints and connections between plates are cast together after the assembly of plates. Plates are further joined together by cast-in-situ topping which is approximately 100 mm thick. The lower surface of the precast deck plates is a smooth formwork finishing. The top surface of the element can be cast with initial double-sided transverse slope. When an existing bridge is being reconstructed and the old and usable concrete deck is partially preserved, it is possible to use precast deck plates which are installed on the existing parts. In this case the plates are thinner and lighter. The top side of the plate can then be cast as a mould surface and the lower surface remains a steel floated one.

Advantages

- Enables to cast the bridge deck in factory conditions

- During the casting of bridge deck and the initial hardening period of concrete there are no fluctuations of the outdoor environment (heat, extreme cold, excessive rain or snow)

- During the first week, concrete hardens in stable indoor conditions, thereby reducing the risk of cracks

- There is no need to use formwork on site and it is significantly easier to build a bridge over a water body that has a changing water level or a river-bed with poor load-bearing capacity

- Safety at construction site improves since the element after assembly becomes immediately a platform for carrying out subsequent works

- Saves construction time since elements can be cast at the factory while preparations are made at the construction site

- Concrete surfaces are of high quality and the dimensions of elements are checked and double-checked before they are delivered to the construction site

Slab parameters

The recommended dimensions of precast slab elements should not exceed 10.0x2.4 m. These dimensions are in the range that allow regular transport and no special permits are needed for carriage.

The maximum mass of one slab is up to 12.5 tons and slabs are carried in pairs.

The time required for assembling one slab is less than 30 minutes.

Assembly

- Bridge deck plates are assembled

- There is a groove in the side edges of deck plates which are equipped with sealings at the factory in order to prevent cement paste from seeping through between elements while joints are being cast

- Horizontal reinforcement is installed in the connections between the slabs

– Dowel joints and connections between the slabs are cast together

- Border elements are assembled

- Reinforcement of the in-situ topping is placed and the topping is then cast

– Joints between border elements are finished with elastic mastics

Scope of works

We offer:

- technical design of the superstructure (precast concrete beams, deck plates and in-situ topping)

- preparing shop-drawings of precast elements;

- preparing shop-drawings of precast elements

- production of precast elements

- delivery of precast elements

- assembly of elements and cast-in-situ works necessary for the integrity of the structure.

T-beam bridges

We have manufactured T-shaped bridge beams which are mainly used for reconstructing old precast beam bridges.

Border and edge elements for bridges

Precast reinforced concrete border and edge elements can have various cross-sections. The shell elements are usually 3-4 m long but we have also manufactured pieces up to 7.5 m long pieces. These elements can be used for both cast-in-situ and composite decks. Elements are fixed with temporary fastenings during assembly and are later connected to the deck by means of protruding rebars or special steel connections. Joints between elements are finished with elastic mastics. Sleeve anchors with internal threads can be cast in the elements for fastening safety barriers. The top and outer surface of elements can be treated with a suitable impregnating substance. The edge element can have a curved design or various patterns including dummy joints, formliner surface or even graphic concrete.